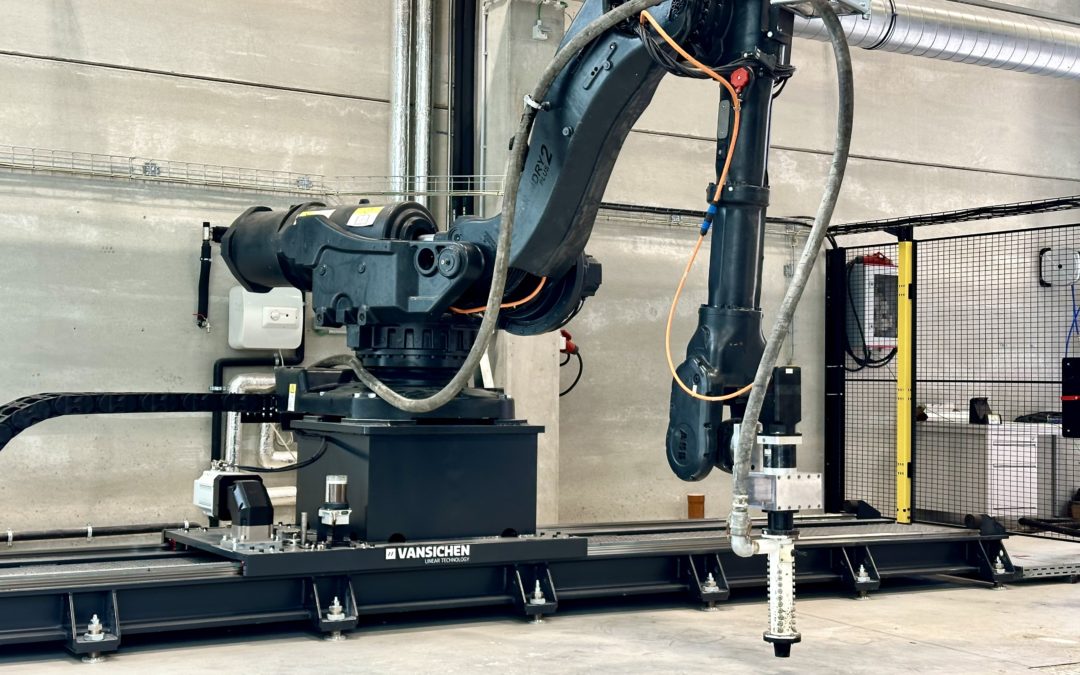

Buildwise – the Center for Construction Research and Innovation, formerly known as “CSTC” – faced a major need for a thorough overhaul of their 3D printing facility, and called on AgiNtech – specialised in automation and industrial robotics – to help them with the analysis, design and implementation of the new installations.

This project to upgrade the concrete 3D printer represents a major step forward in terms of production capacity and efficiency, as well as safety. In fact, the extension of the robot’s work area and revision of the automation process have resulted in a number of innovative technical improvements:

- Extended capacity: thanks to the addition of a 3.7m linear axis (manufactured by Vansichen) to the existing ABB concrete 3D printing robot significantly increased the working area, enabling larger AND more parts to be printed

- Better visibility & increased safety: improved operator safety by implementing a new safety concept, while increasing visibility for visitors with the installation of immaterial fences (Leuze).

- Ease of use: improvements for a more intuitive process.

- Optimized efficiency: reduced set-up time and handling requirements.

- Enhanced quality: improved quality and visibility, making demonstrations more attractive and convincing.

- CE certification: risk analysis for CE certification carried out in collaboration with Vinçotte.

The close collaboration between the 2 teams AgiNtech and Buildwise, their shared commitment, professionalism and technical expertise were key to the success of this major project.